Teaching Laboratory

ME 222: Nature and Properties of Materials

Overview:

Objective is to give a broad understanding of common materials related to mechanical engineering with an emphasis on the fundamentals of structure-property-application relationships.

Course Content:

History of engineering materials, Engineering materials, Materials property chart, Crystal structure, Imperfections of solids, Mechanism of strengthening in metals, Hall-Petch effect, Xray diffraction, Fracture: Ductile, brittle, fatigue. Griffith criterion, S-N curve, Creep, Phase diagram (binary), Iron-carbon system, Heat treatment of metals, Electrical properties, Thermal properties, Magnetic properties, Optical properties, Corrosion, Oxidation, Thermal stability ,

Wear, abrasion, friction of materials, Characterization techniques: Optical microscopy, scanning electron microscopy, transmission electron microscopy, atomic force microscopy, Polymer and its characterization, Viscoleasticity, Nanomaterials and its important properties at nanoscale, Composites: Characterization of composites, Ionic polymer matrix composites, Shape memory alloy, Intelligent Multifunctional materials, Economics, Environment, and

Sustainability In addition to the lectures, the course is associated with a laboratory session. A group of 6/7 students can conduct experiment effectively. A total of six experiments for the duration of 2 hours each is proposed for this course.

Processing Equipment:

Environmental Controlled High Temperature Furnace: Heat treatment in controlled atmosphere

Specification:

Temperature: Room temperature to 1400 0C

Heating rate : 0.5 0C/min to 10 0C/min

Environment : Air, Nitrogen, etc

Location: ACMS 207B

Processing Equipment:

Specimen Cutting Machine- Metallic, polymer, etc

Specification:

RPM- 1500 max

Wheel size: 33 x 2 x 32 mm

Sample size (max): 30 mm x30 mm

Location:ACMS 203B

Processing Equipment:

Single/Double Disc Polishing Machine- Polishing of samples to get smooth surface finish

Specification:

Diameter of disc: 200 mm

Rotation: 300-650 rpm

Location: ACMS 203B

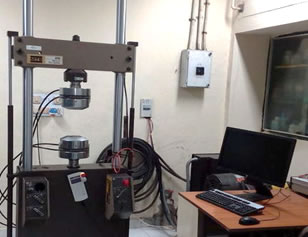

Characterization Equipment:

Universal Testing Machine- Studies of strain-strain behaviour of materials

Specification:

Max force- 100 kN

Cross head speed- 5 mm/min to 100 mm/min

Travel length- 450 mm

Test types- Tension, Compression, and Flexural

Location: NL-1, Room # 112

Characterization Equipment:

MTS 810 Testing Machine- Studies of mechanical properties of materials

Specification:

Max. Force- 100 kN

Travel length- 1308 mm

Controller: Flex test 40

Test types: Tension, compression, bending, and cyclic fatigue

Location: NL-1, Room # 112

Characterization Equipment:

Rotating Beam Fatigue Tester: Studies of fatigue life and endurance limits of metals

Specification:

Load- 10 Kg to 40 Kg

RPM – 1420

Location: ACMS, Room # 207B

Characterization Equipment:

Rotating Beam Reverse Bending Fatigue Testing Machine- Studies of fatigue life and endurance limits of metals

Specification:

RPM- 2800 - 6000

Load- 0.5 kg – 4 Kg

Sample- Dumbbell shape

Diameter of specimen: 8 mm

Location: ACMS 207B

Characterization Equipment:

Rotating Beam Reverse Bending Fatigue Testing Machine - Studies of fatigue life and endurance limits of metals

Specification:

Diameter of test specimen: 8 mm Maximum bending moment: 500 Kg. cm.

RPM- 1425

Load- 0.250 Kg to 50 Kg

Location: ACMS 207B

Characterization Equipment:

Shore A Durometer- Measurement of hardness for soft materials like rubber

Specification:

Preload: 0.45 Kgf

Major Load: 8.06 N

Indentor type- 35° truncated cone indenter

Type of load- Constant contact pressure

Location: ACMS 207B

Characterization Equipment:

Shore D Durometer- Measurement of harness for hard polymer

Specification:

Preload: 0.45 Kgf

Major Load: 44.48 N

Indentor type- 30° cone indenter

Type of load- Constant contact pressure

Location: ACMS 207B

Characterization Equipment:

Portable Hardness Tester- Rockwell hardness tester for measurement of hardness

Specification:

Rockwell test

Load – 10 Kg, 60 Kg, 100 Kg and 150 Kg

Indentor: Diamond /

1/16” ball

Location: ACMS 207B

Characterization Equipment:

Poldi Hardness Tester- Measurement of hardness

Specification:

Preload: 0.42 Kgf

Major Load: Hammer blow

Material - Alloy steel EN-8 OR EN-9

Dia- 30mm

Length- 85 mm

Tungsten Carbide Ball

Dia- 10 mm

Poldy Bar

Material: Alloy steel EN-8 or EN-9 or Carbon Steel- WPS

Size- 12 mm X 12mm X 150 mm

Eyepiece- 8X, 25 X

Location: ACMS 207B

Characterization Equipment:

Ellipsometer- Thickness of thin film

Specification:

Range: 10 nm – 400 nm

Source – Green laser, 532 nm

Location: ACMS 203F

Characterization Equipment:

Metallography Station Trinolcular Optical Microscope with Camera- To study surface morphology

Specification:

Magnification- 25 X to 1200X

Focusing: Coarse to fine

Head: Monocular, binocular/trinocular

Illumination- Halogen, incident light

Eye piece: 5X, 10X, 15X and 20 X

Objective: 5X, 10X 20X and 40X

Location: NL-1, Room # 112

Characterization Equipment:

Surface Roughness Tester- Measurement of surface hardness

Specification:

Range: 350 m (-200 m to 150 m)

Detecting mode: Skid measurement

Measuring force: 4mN or 0.75 mN (Low force type)

Stylus tip: Diamond, 900/mR (600/2mR: low force type)

Travelling length : 6 mm

Evolution length (mm) : 1.25, 4.0

Location: ACMS 207B

Characterization Equipment:

Superficial Rockwell Tester

Specification:

Range: 350 m (-200 m to 150 m)

Detecting mode: Skid measurement

Measuring force: 4mN or 0.75 mN (Low force type)

Stylus tip: Diamond, 900/mR (600/2mR: low force type)

Travelling length : 6 mm

Evolution length (mm) : 1.25, 4.0

Location: ACMS 207B

Characterization Equipment:

Brinell Hardness Tester- Brinell hardness test of Metals

Specification:

Preload: 250 Kgf

Major Load - 250-3000 Kgf in range of 250 Kgf

250, 500, 750, 1000, 1250, 1500 Kgf

Maximum test height- 410 mm

Depth of throat- 205 mm

Max depth of spindle below base – 180 mm

Steel ball diameter (Indentor)- 10 mm , 5 mm, 2.5 mm

Location: ACMS 203B

Characterization Equipment:

Vickers Hardness Tester- Vickers hardness tester of metals

Specification:

Load- 5 Kgf to 50 Kgf

30, 40, 50 Kgf (loads 5, 10, 15, 20 not working properly)

Indentor – diamond

Magnification- 25 X

Location: ACMS 203B

Associate Faculty: Prof. Kamal K. Kar, Prof. Bishakh Bhattacharya, Prof. J. Ramkumar

Staff: Mr. Suresh Chendra

Contact Person: Mr. Suresh Chendra