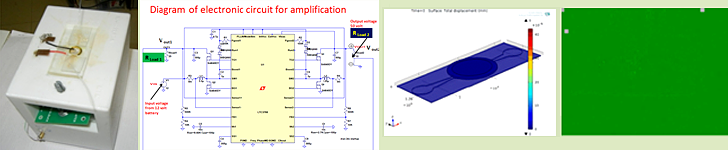

Piezo-based micro pump

Research is focused on the following key areas: manufacturing systems, manufacturing processes, additive manufacturing, welding, casting, advanced machining processes, micro/nano fabrication and finishing, nanotechnology, bioengineering, nano-composites, MEMS, laser/plasma surface coating, large deformation systems, CAM of advanced engineering materials, polymer processing and rheology, lab on chip, vibration control of machine tools, adaptive control system, unconventional machining, solid-liquid phase change (melting/solidification).

Participating Faculty

Research Laboratories

| Manufacturing Lab |

|

| Micro systems Fabrication Laboratory | Wire Bonder, Desk Top Mask Aligner, DI water system, Chemical Balance, Fume Hood, Gravity Convection Oven, Optical Table, Spin Coater, Air cooled Chiller, Sputtering / PECVD Dual System, Oxidation Furnace, Dicing Saw |

| Solidification Laboratory | In-situ PIV, PLIF and HR imaging facility for melting/solidfication, In-situ experimental and HR imaging facility for droplet impact on surfaces, Laser welding, Experimental facility for PCM based thermal storage, Opensource software for additive manufacturing, welding, casting, thermal spray coating, thermal storage. |

| Additive Manufacturing Facility | Laser powder bed fusion based metal 3D printing equipment |

| Computational Manufacturing Systems Laboratory | Individual desktop workstations |

| Advanced Nano-engineering Materials Laboratory | AFM, SEM, Raman, DSC, TGA, DMA, UTM, PECVD, etc |